Infrared temperature readings can be pretty accurate, but it depends on a few factors. Here’s what I mean: 1) Emissivity matters—different materials emit heat differently. 2) Check the distance-to-spot ratio; larger discrepancies can happen if you’re too far. 3) Regular calibration helps maintain precision. Finally, environmental conditions like humidity or dust can throw off your readings. So, make sure you know these factors to get the best results. Stick around, and I’ll share more tips to optimize your measurements!

Key Takeaways

- Infrared thermometers can achieve skin temperature accuracy of ±0.3 °C if properly calibrated and used according to standards like ASTM E1965-98.

- Emissivity factors significantly affect accuracy, as materials with low emissivity can yield misleading temperature readings.

- The distance-to-spot ratio determines the area measured; higher ratios allow accurate readings from further away, reducing contamination from surrounding temperatures.

- Regular calibration using methods like ice water or boiling water enhances measurement reliability and accuracy of infrared thermometers.

- Environmental factors such as ambient temperature, humidity, and obstructions like dust can significantly influence the accuracy of infrared temperature readings.

Understanding Infrared Temperature Measurement Accuracy

When it comes to understanding infrared temperature measurement accuracy, you might find it helpful to know that not all infrared thermometers are created equal. Here are a few key points to examine:

- Infrared Principles: These devices detect heat emitted by objects, but accuracy can vary widely based on design and calibration.

- Measurement Techniques: Standards like ASTM E1965-98 set accuracy for skin temperature at ±0.3 °C. That’s pretty tight!

- Calibration Matters: Regular calibration against recognized standards is essential. Think of it like tuning a guitar—it’s all about getting the right sound!

- Environmental Factors: Don’t forget, things like ambient temperature and surface conditions can throw off readings.

Factors Influencing Accuracy: Emissivity

Understanding emissivity is crucial for getting accurate infrared temperature readings. Here’s why:

- Material Types Matter: Different materials have emissivity variations. Metals can have low emissivity, while ceramics often score high.

- Surface Conditions: A polished surface reflects more radiation, affecting readings. If it’s rough or oxidized, expect higher emissivity values.

- Emissivity Impact: Low-emissivity surfaces might cause your thermometer to misread temperatures. You could end up with numbers that are way off!

- Adjusting Emissivity: Many IR thermometers let you adjust for emissivity. This feature guarantees more accurate results across various materials.

The Importance of Distance-to-Spot Ratio

The distance-to-spot ratio is a key player in getting accurate infrared temperature readings. This ratio defines the area measured at a given distance, like 12:1, meaning you get a 1-inch spot from 12 inches away. Here’s why it matters:

- Distance Impact: The farther you measure, the larger the spot size, which can lead to surrounding temperatures contaminating your results.

- Measurement Precision: A higher ratio allows for accurate readings even at longer distances, vital for industrial settings.

- Target Size: For smaller targets, you need a closer range.

Choosing the right ratio based on your needs is essential. So, whether you’re in the kitchen or a workshop, balance accuracy with practical use—trust me, it’s worth it!

Calibration Practices for Enhanced Accuracy

Calibration practices are essential if you want to enhance the accuracy of your infrared temperature readings. Here are some key calibration techniques you should consider:

- Ice Water Method: Mix ice and water for a stable 32°F (0°C) point. It’s reliable and easy.

- Boiling Water Method: Use boiling water (212°F/100°C) as a reference, but watch out for steam!

- Infrared Comparator Cups: These are great for multi-point calibration without breaking the bank.

- Industrial Black Body Calibration: For serious accuracy, this is the gold standard in labs.

Environmental Conditions Affecting Readings

While you might think that infrared (IR) thermometers simply read temperatures without a hitch, various environmental conditions can throw a wrench in the works. Here are a few key factors to take into account:

- Temperature Variations: Ambient temperatures can affect the device’s internal workings, leading to inaccurate readings.

- Humidity Effects: High humidity can absorb IR radiation, lowering signal strength and potentially causing condensation on the sensor.

- Particulates: Dust, smoke, or steam can obstruct the IR path, leading to skewed readings.

- Distance Matters: The farther you are from the target, the more atmospheric interference you’ll encounter.

Advances in Infrared Measurement Technology

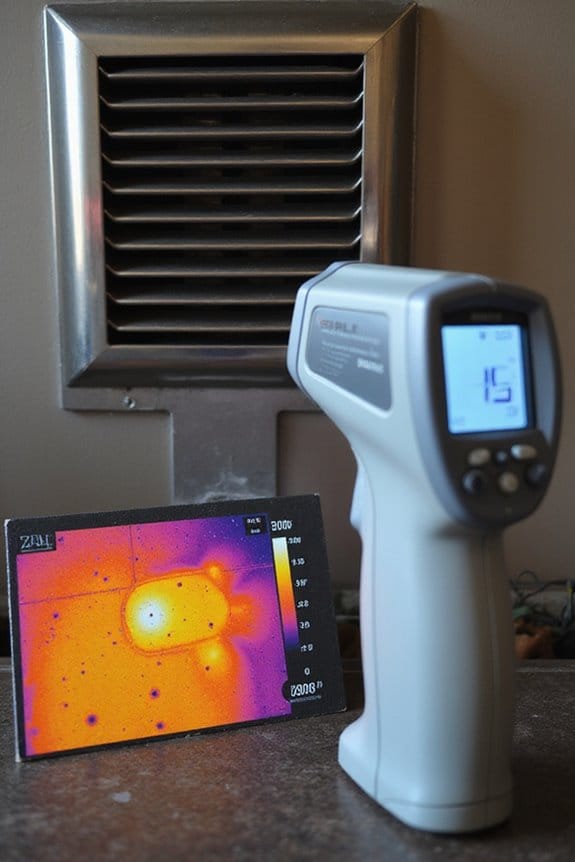

As we explore the world of infrared measurement technology, you’ll find that recent advances are making these devices more accurate and user-friendly than ever before. Here are a few exciting developments:

- Sensor Innovations: Germanium-based waveguide-integrated photodetectors now allow for broad-spectrum mid-infrared detection at room temperature. This means no cooling hassles!

- Measurement Techniques: Modern infrared thermometers have improved response times and accuracy, thanks to advances in sensor design.

- Digital Integration: Miniaturized sensors with ASICs simplify integration and enhance out-of-the-box accuracy.

These innovations not only boost precision but also open doors for applications in medicine, industry, and environmental monitoring. Additionally, advancements in thermal imaging camera resolutions are enhancing diagnostic accuracy across various fields. I’d say, if you’re considering upgrading your thermometer, now’s a great time!

Common Sources of Error in Infrared Thermometry

When it comes to infrared thermometry, understanding common sources of error can be a game changer in achieving accurate readings. Here are a few key points to reflect on:

- User Influence: Incorrectly setting emissivity can lead to significant measurement errors. Always double-check those settings!

- Sensor Limitations: Remember, sensors can struggle with shiny or reflective surfaces. They need direct infrared radiation to work well.

- Surface Types: Different materials emit infrared radiation differently. For example, metal surfaces can be tricky due to their reflectiveness.

- Measurement Techniques: Misalignment of the sensor while measuring can give you a false reading. Aim carefully!

Best Practices for Accurate Infrared Temperature Readings

To achieve accurate infrared temperature readings, it’s essential to follow some best practices that help minimize errors and boost reliability. Here are my top tips:

- Understand D:S Ratio: Keep your infrared thermometer close enough. Check the distance-to-spot (D:S) ratio in the specs. A 12:1 ratio means measure 1 inch at 12 inches away.

- Use Laser Guides Wisely: Treat the laser pointer as an aiming tool, not a measurement guide. The actual spot size is wider than it looks!

- Choose the Right Sensor: Pick infrared sensor types based on your target’s temperature and material.

- Keep Conditions Stable: Try to measure in consistent environments to avoid unexpected readings.

Following these techniques can greatly improve your accuracy. Happy measuring!

Frequently Asked Questions

How Does Infrared Thermometry Compare to Contact Thermometers?

Infrared thermometry offers non-contact advantages, making it quick and hygienic. However, I’ve found that contact thermometers generally provide better measurement accuracy, especially when precision is critical in medical settings. It’s all about context!

Can Infrared Thermometers Measure Temperature Through Transparent Surfaces?

I’ve found that infrared thermometers can’t accurately measure temperature through transparent materials. They often read the surface emissivity instead, leading to misleading results. It’s best to avoid using them through any transparent barriers.

Are Infrared Temperature Readings Safe for All Surfaces?

While infrared thermometers offer surface compatibility, I’ve found that temperature accuracy can vary. They’re safe for most surfaces, but reflective materials may lead to misleading readings if emissivity isn’t properly adjusted. Always double-check!

What Is the Lifespan of an Infrared Thermometer?

I’ve found that an infrared thermometer typically lasts 5 to 10 years, but battery longevity and usage frequency can really affect that. Proper care and maintenance can help extend its lifespan notably.

How Often Should I Calibrate My Infrared Thermometer?

Hey there, fellow time traveler! I’d recommend calibrating your infrared thermometer every 6 to 12 months, especially for critical applications. Keeping up with calibration frequency guarantees your thermometer accuracy stays excellent and reliable for all your needs!