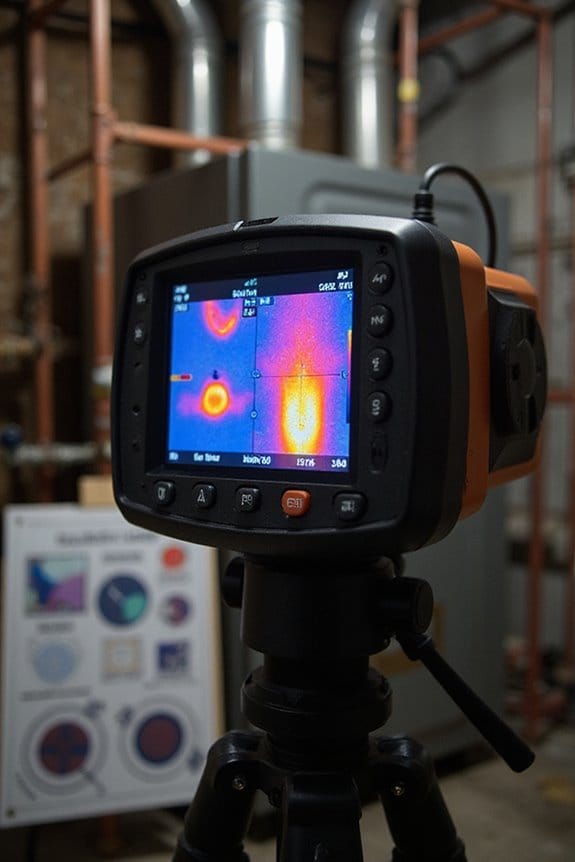

In thermal testing, spectral range is all about the specific wavelengths a device can detect. It’s essential for measuring how materials absorb and emit heat. There are a few common ranges: 1) Near-infrared (0.75-1.4 µm), 2) Short-wave infrared (1.4-3 µm), 3) Mid-wave infrared (3-5 µm), and 4) Long-wave infrared (8-14 µm). Each range has its unique perks, and choosing the right one minimizes temperature reading errors. Stick around, and I’ll share more about its applications and upcoming trends!

Key Takeaways

- Spectral range refers to the specific segment of wavelengths detectable by thermal testing instruments, measured in nanometers or micrometers.

- Different spectral ranges, such as LWIR and MWIR, are tailored for various thermal applications and material properties.

- Proper selection of spectral range minimizes temperature reading errors caused by emissivity variations across materials.

- Calibration with blackbody references is essential for accurate thermal measurements within the chosen spectral range.

- Future advancements in thermal imaging technology will enhance resolution, sensitivity, and integration capabilities across various industries.

Definition of Spectral Range

When we talk about the spectral range, we’re diving into an important part of the electromagnetic spectrum. In essence, the spectral range refers to the specific segment of wavelengths that an instrument can detect. Here’s a quick breakdown:

- Definition: It’s the range of wavelengths, expressed in nanometers (nm) or micrometers (µm), that can be measured.

- Wavelength Limits: Different applications require different wavelength limits. For instance, thermal cameras typically operate between 3 µm and 14 µm.

- Importance: Understanding the spectral range is critical because it directly affects the accuracy of data collected.

Common Spectral Ranges Used in Thermal Cameras

Understanding the common spectral ranges used in thermal cameras can feel like traversing a maze of wavelengths, but it’s essential for effective thermal testing. Here’s a quick breakdown:

- NIR Applications (0.75 – 1.4 µm): Great for high temperatures above 450°C, offering high thermal sensitivity and accuracy.

- SWIR Advantages (1.4 – 3 µm): Important for specialized thermal imaging, especially in multispectral setups, thanks to unique emissivity effects.

- MWIR Limitations (3 – 5 µm): Useful for gas detection but sensitive to atmospheric interference.

- LWIR Features (8 – 14 µm): The most common range, perfect for a wide array of applications, measuring from -50°C to 900°C.

Selecting the right range is key for accurate pyrometry techniques and effective temperature measurement. Additionally, understanding image quality resolution is crucial for interpreting thermal data accurately.

Importance of Spectral Range Selection

Selecting the right spectral range for thermal testing isn’t just a technical detail; it’s a game-changer for accuracy. Here’s why it matters:

- Minimized Errors: The right spectral range reduces temperature reading errors, especially with high temperatures.

- Emissivity Impact: Mismatched ranges lead to inaccurate readings due to emissivity variations.

- Material Suitability: Different materials emit infrared radiation uniquely, so choosing the right range is essential.

- Sensitivity Boost: A well-matched spectral range enhances thermal camera sensitivity and improves detection of small temperature differences.

Measurement and Calibration Considerations

While you might think that measuring thermal properties is straightforward, there’s a lot that goes into ensuring accuracy and reliability in your results. Here are some key considerations:

- Calibration Standards: Use blackbody references for known emissivity; these are essential for accurate measurements.

- Reference Materials: Employ certified materials with known spectral emissivity values across wavelengths.

- Measurement Techniques: Fourier-transform infrared (FTIR) spectrophotometers are great for broad coverage.

- Temperature Effects: Remember, emissivity can change with temperature, so keep that in mind during calibration.

- Environmental Factors: Ambient conditions and sample preparation can impact your readings.

Applications of Spectral Range in Thermal Testing

When it comes to thermal testing, the right spectral range can make all the difference in your results. Here are some key applications that showcase this:

- Material-Specific Measurements: Choosing the right spectral range enhances measurement precision, targeting materials with distinct emissivity values for improved spectral accuracy.

- Through Semi-Transparent Media: Selecting spectral ranges allows thermal measurements through materials like glass, maintaining thermal sensitivity and avoiding signal loss.

- Gas Detection: Using the mid-wave infrared (MWIR) range helps identify gas leaks effectively, improving safety in industrial settings.

- Industrial Monitoring: Spectral thermography can detect insulation defects during manufacturing, vital for quality control.

In short, the right spectral range isn’t just a technical detail; it’s essential for getting accurate thermal results!

Technical Specifications and Sensor Types

Understanding the technical specifications of thermal sensors is essential, especially since the right choice can greatly impact your thermal testing results. Here’s a quick guide to help you:

- Detector Materials: Different materials suit various spectral ranges:

- Si detectors work up to 1 µm.

- PbS and InGaAs are effective from 1-3 µm.

- HgCdTe covers 3-15 µm.

- Short-Wave IR (SWIR): 1-3 µm, overlaps with visible light.

- Mid-Wave IR (MWIR): 3-6 µm, perfect for gas detection.

- Long-Wave IR (LWIR): 6-15 µm, ideal for room temperature objects.

Keep in mind, sensor performance can vary based on these specifications. So, choose wisely!

Differences Between MWIR and LWIR

As you plunge into the differences between MWIR and LWIR, you’ll notice that each has its unique strengths tailored for specific applications. Here’s a quick breakdown:

- MWIR Advantages: It excels in high-resolution imaging, capturing finer details in hotter scenes. If you need precise target identification, MWIR is your go-to.

- LWIR Limitations: While it’s effective for general thermal imaging, LWIR struggles with resolution due to longer wavelengths, leading to fuzzier images.

- Cost and Complexity: MWIR cameras are pricier due to cooled detectors, making them complex. In contrast, LWIR systems are often uncooled, simpler, and more budget-friendly.

Ultimately, your choice depends on whether you prioritize detail or cost. So, what’s your mission? Choose wisely!

Effects of Atmospheric Conditions on Spectral Range

Choosing between MWIR and LWIR isn’t just about resolution or cost; atmospheric conditions also play a big role in how effectively thermal sensors perform. Here’s what you should know:

- Atmospheric Absorption: Gases like water vapor and carbon dioxide absorb infrared radiation, creating windows around 3-5 µm and 8-14 µm. These are essential for thermal imaging.

- Scattering Effects: Particulates in the air scatter infrared radiation, especially at shorter wavelengths, which can limit detection distance.

- Weather Matters: Rain, fog, or snow increase absorption and scattering, narrowing your effective spectral range.

In clear conditions, thermal imaging shines. So, always check the weather before heading out! It could make all the difference in your thermal testing results.

Future Trends in Thermal Imaging Technology

While it might seem like thermal imaging technology has already reached its peak, there are exciting trends on the horizon that promise to revolutionize the field. Here’s what to look forward to:

- Future Advancements in Resolution: By 2025, thermal cameras will boast resolutions of 640×480 pixels or higher, making images clearer and analyses more accurate.

- Technology Integration with AI: Expect AI to play an essential role in automatic recognition and faster decision-making, especially in public safety.

- Multispectral Imaging: Combining thermal with RGB sensors will enhance our ability to analyze scenes thoroughly.

- Cooled Cameras: With improved sensitivity and reduced noise, cooled thermal cameras will dominate industries like aerospace and research.

- Enhanced Power Efficiency: Innovations in power efficiency will allow thermal cameras to operate longer on a single charge, making them more user-friendly for extended outdoor use.

These trends promise to make thermal imaging more accessible and effective than ever!

Frequently Asked Questions

How Does Spectral Range Affect Thermal Camera Pricing?

I’ve noticed that spectral sensitivity plays a huge role in thermal camera pricing factors. Cameras with specialized ranges often cost more due to advanced technology and materials, while general-purpose models remain more affordable for broader applications.

Can Different Materials Emit in Multiple Spectral Ranges?

Absolutely, I’ve seen different materials emit across multiple spectral ranges. Through spectral analysis, I can pinpoint these emissions, revealing unique thermal characteristics that enhance my understanding of each material’s behavior in various thermal environments.

What Safety Precautions Are Needed When Using Thermal Cameras?

When using thermal cameras, I always prioritize thermal camera safety. I follow infrared imaging precautions, wear appropriate PPE, avoid direct eye exposure to lasers, and guarantee the environment is controlled to maintain accurate readings.

How Does Ambient Temperature Influence Thermal Measurements?

Did you know that temperature variations can cause calibration drift of less than ±1%? I find that ambient influences considerably affect thermal measurements, making accurate adjustments essential for reliable readings in different environments.

Are There Legal Regulations Regarding Thermal Imaging Usage?

Yes, there’re legal implications surrounding thermal imaging usage. I’ve found that various imaging standards exist to regulate its application, particularly regarding privacy rights and ethical considerations, ensuring responsible use across different sectors and jurisdictions.