For storing your tools, I recommend keeping them in a temperature range of 50°F to 75°F (10°C to 24°C). This helps maintain their durability and performance. Avoid temperatures below freezing, which can make plastics brittle, and steer clear of anything above 80°F (27°C) to prevent corrosion. A stable environment is key, so consider using tool chests or cabinets to buffer against fluctuations. Want to know more about humidity and how it affects your tools?

Key Takeaways

- Store tools in an ideal temperature range of 50°F to 75°F (10°C to 24°C) to ensure durability and performance.

- Avoid temperatures below freezing to prevent brittleness in plastic and rubber components.

- Keep storage temperatures below 80°F (27°C) to minimize corrosion and maintain lubrication effectiveness.

- Regularly monitor humidity levels, as high humidity can accelerate rust, especially in warmer conditions.

- Use insulated storage solutions and silica gel packets to manage temperature fluctuations and moisture.

Recommended Temperature Ranges for Tool Storage

When it comes to storing tools, you might not think temperature matters much, but it really does! Keeping tools in the right temperature range can greatly enhance their lifespan and prevent material degradation. Here are some key points to take into account:

- Ideal Range: Aim for 50°F to 75°F (10°C to 24°C). This helps maintain durability.

- Avoid Cold: Temperatures below freezing can make plastic and rubber parts brittle.

- Watch the Heat: Storing above 80°F (27°C) can speed up corrosion and mess with lubrication.

- Humidity Matters: Keep humidity in check to minimize rust and fatigue.

Regularly check your storage environment with a thermometer. Trust me, your tools will thank you!

Effects of Temperature on Tool Materials

While it might not seem like a big deal, the temperature at which you store and use your tools can have a massive impact on their performance and longevity. Here are a few key effects of temperature:

- Elevated Temperatures: They can reduce material stiffness and strength, making your tools less durable. Yikes!

- Low Temperatures: While they increase stiffness, they can also lead to material brittleness. This means your tools might crack when you need them most.

- Thermal Expansion: Constant temperature changes can cause unwanted stresses, leading to deformation and wear.

- Creep Deformation: Over time, heat can lead to changes in shape if your tools are under constant load.

Humidity and Temperature Interaction

Understanding how humidity and temperature interact is essential for anyone who wants to keep their tools in top shape. Here’s what I’ve learned about this dynamic duo:

- Temperature Effects: Higher temperatures speed up molecular vibrations, which can lead to expansion and quicker chemical reactions that deteriorate tools.

- Humidity Control: When humidity rises, it increases moisture levels, making metal tools susceptible to rust.

- Corrosion Acceleration: Combine high humidity with elevated temperatures, and corrosion rates skyrocket!

- Stability Matters: Keeping a stable temperature minimizes fluctuations in humidity, protecting your tools from repeated swelling and contraction.

- Ventilation is Key: Good airflow can prevent humidity buildup and keep your tools safe from the elements.

- Measurement Accuracy: Using tools with 5% RH accuracy can help ensure that you maintain the ideal conditions for your tool storage.

Best Practices for Tool Storage Temperature Control

Proper temperature control can make all the difference in keeping your tools in great shape. Here are some best practices I’ve found useful for tool organization and storage solutions:

- Maintain Room Temperature: Aim for 15°C to 25°C (59°F to 77°F) to prevent damage.

- Avoid Extremes: Keep tools away from temperatures below 0°C (32°F) or above 38°C (100°F) to protect materials.

- Use Insulated Storage: Tool chests and cabinets help buffer against temperature swings.

- Check Regularly: Monitor your storage area for consistent temperatures and signs of condensation.

- Seal and Protect: Use original cases and add silica gel packets to keep moisture at bay.

Following these tips will keep your tools happy and ready to work when you are!

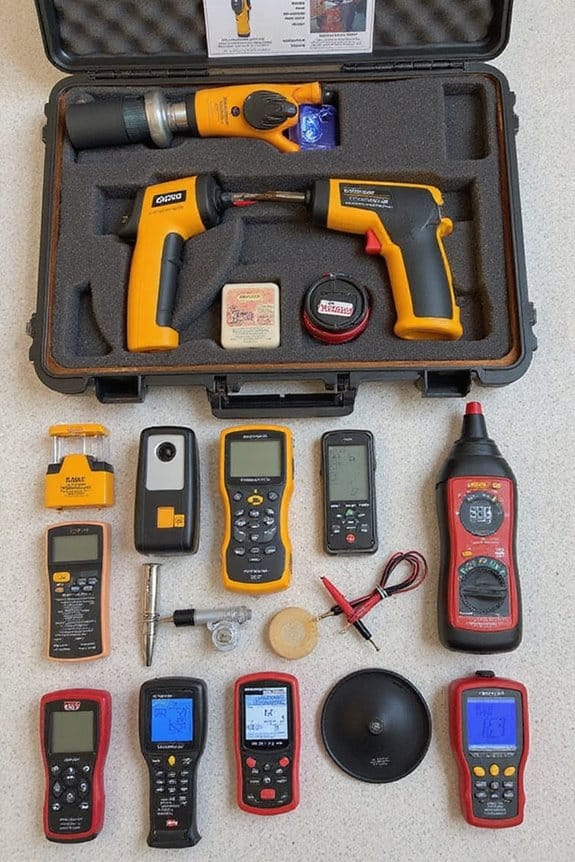

Temperature Considerations for Specific Tool Types

When it comes to storing different types of tools, temperature considerations can really make or break their performance and longevity. Here are some key points for tool care:

- Power Tools: Aim for 40°F to 80°F (4°C to 27°C). Cold can thicken lubricants and drain battery life.

- Pneumatic Tools: Keep them in stable temperatures to protect seals and hoses.

- Metal Hand Tools: They handle wider ranges, but below freezing increases rust risk.

- Cordless Battery Tools: Store above freezing to prevent faster discharge.

- Specialty Tools: Best kept between 50°F to 77°F (10°C to 25°C) to safeguard electronics. Proper storage aligns with durability and quality to ensure tools perform optimally over time.

Don’t forget those seasonal adjustments! Proper temperature storage helps keep your tools in top shape for when you need them.

Consequences of Improper Temperature Storage

Improper temperature storage can lead to some serious consequences, and trust me, you don’t want to find out the hard way. Here’s a quick consequences overview:

- Material Damage: Extreme heat can warp metal and spoil plastics, while cold makes them brittle. You might end up with broken tools in your hands!

- Corrosion: Fluctuating temperatures and humidity create rust. This can ruin both the functionality and looks of your tools.

- Mold Growth: Warm, humid conditions invite mold. This can damage grips and cases, plus it’s not great for your health.

- Safety Hazards: Weak tools can malfunction, leading to injuries. Trust me, you don’t want a tool failure when you’re in the middle of a project!

Monitoring Temperature and Humidity

Keeping an eye on temperature and humidity can save you from a lot of headaches down the road. Here are some key points to take into account:

- Choose the Right Sensors: Thermocouples and thermistors work well for temperature monitoring, while electronic humidity sensors are your go-to for moisture levels.

- Sensor Calibration: Regular calibration is vital. It guarantees your readings are accurate, preventing unexpected surprises.

- Data Logging: Opt for data loggers that track conditions over time. They help spot trends and identify issues before they escalate.

- Placement Matters: Position sensors in areas where temperature and humidity might fluctuate, guaranteeing even monitoring throughout your storage.

With the right monitoring tools and techniques, you’re setting yourself up for success, keeping your tools safe and sound!

Tips for Maintaining Ideal Storage Conditions

To maintain the ideal storage conditions for your tools, it’s essential to create an environment that minimizes risks from temperature and humidity. Here are some tips that have worked for me:

- Control Temperature: Keep the storage area between 65°F and 70°F. Consistent temperatures reduce thermal stress on your tools.

- Manage Humidity: Aim for a relative humidity of 30% to 50%. Using desiccants can help absorb excess moisture.

- Ensure Airflow: Good air circulation helps reduce humidity. A well-ventilated space is key.

- Apply Coatings: Consider using corrosion-resistant coatings for added protection against environmental factors.

- Regular Inspections: Check your tools often for signs of moisture or damage. Prevention is always better than cure! Additionally, monitoring moisture levels can help you maintain a safe environment for your tools.

Frequently Asked Questions

Can I Use a Regular Thermometer for Monitoring Tool Storage Temperature?

I wouldn’t rely solely on a regular thermometer for temperature monitoring in tool storage. They lack precision and features like alarms, which are essential for maintaining ideal conditions and preventing potential damage to my tools.

How Often Should I Check the Temperature in My Tool Storage Area?

As I stroll through my tool storage, I can’t help but feel the importance of regular temperature monitoring. I check it every few months, adjusting storage frequency based on the tools’ sensitivity to guarantee they’re always safe.

What Types of Tools Are Most Affected by Temperature Fluctuations?

I’ve noticed that power tools and hand tools are particularly vulnerable to temperature sensitivity. Fluctuations can compromise material integrity, leading to malfunctions or reduced lifespan. It’s essential to store them in stable conditions for ideal performance.

Do I Need to Worry About Sunlight Exposure in Storage?

Storing tools without UV protection is like leaving a car in the sun; it’ll fade and deteriorate. I definitely worry about sunlight damage. Using proper storage keeps my tools safe and extends their lifespan considerably.

Is It Necessary to Insulate My Tool Storage Space?

I believe insulating my tool storage space is essential. Using insulation materials helps maintain temperature control, preventing fluctuations that can damage tools. It guarantees a stable environment, extending their lifespan and reliability for future projects.