Moisture meters vary in how deep they can read. Here’s a quick breakdown:

- Pinless meters: Typically read up to 3/4 inch deep.

- Pin meters: Can go several inches, targeting moisture hotspots.

- Dual-depth meters: Measure both shallow and deep levels, up to 1 1/4 inches or more.

Each type has its strengths. So, if you’re aiming to find hidden dampness, stick around. There’s more to explore on choosing the right meter for your needs!

Key Takeaways

- Pinless moisture meters typically measure up to 3/4 inch (19mm) deep, with some advanced models allowing for depth adjustments.

- Pin type meters can penetrate several inches into wood, focusing on specific moisture hotspots for deeper readings.

- Dual-depth meters provide measurements for both shallow (up to 3/8 inch) and deep (1 1/4 inch or more) moisture levels.

- Most pinless meters have a general measurement limitation of less than an inch for accurate readings across various materials.

- Specialized meters, like infrared types, can measure moisture at varying depths but are primarily used in laboratory settings.

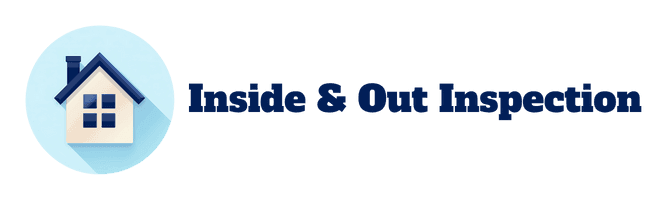

Types of Moisture Meters

When it comes to moisture meters, think of them as your trusty sidekick in the battle against dampness. There are several types to evaluate:

- Pin Type Meters: These use invasive probes to measure moisture directly. They give precise readings, but they can leave tiny pinholes behind.

- Pinless Meters: No probes here! They emit electromagnetic waves, making them perfect for non-invasive testing.

- All-in-One Meters: Combining both pin and pinless technology, these are versatile and adapt to your needs.

- Specialized Meters: These advanced tools, like infrared meters, are for precise research in labs, not your average home inspection.

- Search Mode Meters: Focused on scanning large areas, they help find hidden moisture before you plunge into invasive methods.

Additionally, moisture detection tools are essential for homeowners to prevent mold growth and water damage.

Pick wisely!

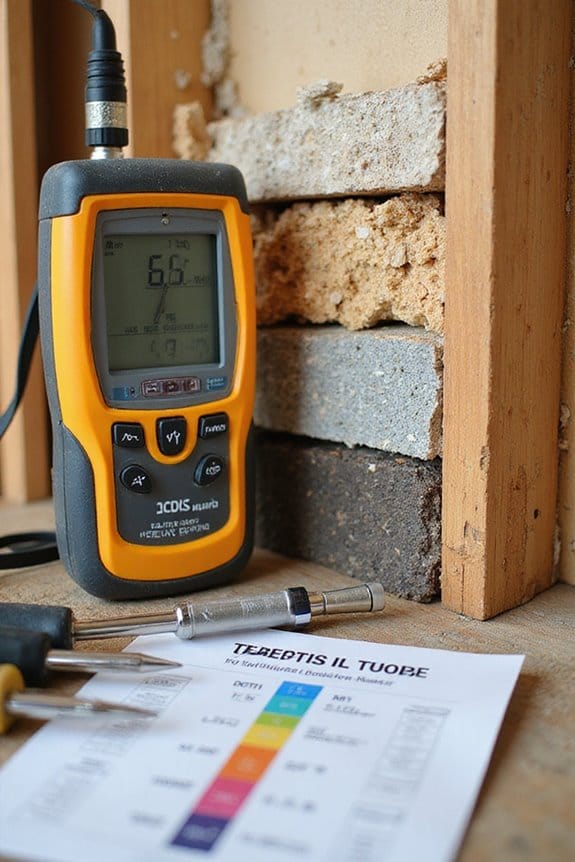

Typical Depth Ranges

Understanding typical depth ranges for moisture meters is essential if you’re serious about tackling moisture issues. Here’s what I’ve learned about moisture detection:

- Pinless Meters: They generally measure up to 3/4 inch (19mm). Some advanced models let you adjust the depth based on material thickness. Still, it’s less than an inch for most brands.

- Pin Meters: With longer pins, they can penetrate several inches into wood. This means they focus on moisture hotspots, which is pretty nifty!

- Dual-Depth Meters: These clever devices measure both shallow (up to 3/8 inch) and deep (1 1/4 inch or more) moisture levels, helping you pinpoint issues more effectively. Additionally, moisture meters with multiple measurement modes can enhance your ability to detect moisture accurately across various materials.

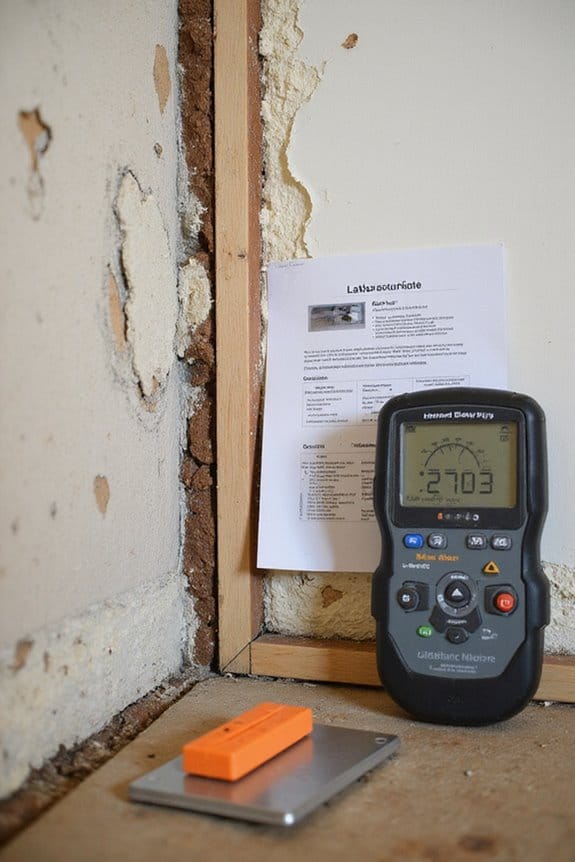

Measurement Accuracy Variables

Now that we’ve covered typical depth ranges for moisture meters, let’s talk about what can mess with their accuracy. Here are a few key variables:

- Calibration Techniques: Regular calibration is a must. If your meter isn’t calibrated, it can give you wrong readings, even if it’s a fancy model!

- Environmental Influences: Temperature and humidity can really throw things off. High humidity might make your readings look higher than they are.

- Material Differences: Different materials behave differently. A correction factor is often needed to get accurate moisture content.

- Stable Conditions: Try to measure in stable conditions to avoid misleading fluctuations. Additionally, calibration options can enhance measurement precision across various materials.

Common Material Applications

Moisture meters play an essential role in various material applications, ensuring we get accurate readings where it counts. Here are some common uses:

- Wood Types: Different wood types need calibration adjustments. For instance, softwoods and hardwoods absorb moisture differently, impacting their moisture effects.

- Concrete and Masonry: These meters can measure up to 50 mm deep, making them ideal for evaluating moisture levels in foundations.

- Drywall: Monitoring moisture in drywall is critical to preventing mold. It typically measures between 1.5% to 33%.

- Specialized Sensors: Pin and pinless meters offer flexibility, with pinless types allowing deeper readings without damage. Additionally, using a moisture meter can help identify hazardous conditions related to mold and water damage.

Understanding these applications helps us choose the right meter for our needs—because no one wants a soggy situation!

User Considerations

While using a moisture meter might seem straightforward, a few considerations can make a big difference in the accuracy of your readings. Here are some key user considerations to keep in mind:

- Training Resources: Familiarize yourself with your meter. Proper training helps you interpret readings accurately.

- User Experience: Inconsistent use can lead to errors. Guarantee a firm, flat contact for pinless meters to avoid inaccuracies.

- Environmental Effects: Be aware that temperature and humidity can distort readings. Adjust accordingly!

- Calibration: Regularly calibrate your device and use the correct settings for different materials. Additionally, understanding calibration procedures is crucial for maintaining reliable measurements.

Technical Limitations

When it comes to using moisture meters, there are several technical limitations you should be aware of. Here are some key points:

- Depth Limitations: Pin-type meters only measure moisture up to about 3/4 inch deep due to pin penetration. Pinless meters have a similar range—typically around 1/2 inch—due to electromagnetic signal strength.

- Material Impact: The density and composition of the material can affect depth accuracy. For example, embedded metals can throw off readings considerably.

- Calibration Challenges: Over time, calibration can drift, leading to inaccurate readings, especially at depth. Low-quality meters often struggle with this.

- Surface Moisture: Surface conditions can distort readings, making it tricky to get reliable results.

Best Practices for Accurate Readings

Understanding the technical limitations of moisture meters lays the groundwork for achieving accurate readings. Here are some best practices for your moisture assessment:

- Consistent Depth: Insert pins to the same depth. This prevents variability in readings.

- Stable Contact: Keep pinless meters flat against surfaces. Even pressure is key!

- Correct Settings: Always select the right material type on your meter. Different materials behave differently.

- Multiple Measurements: Measure several times at the same spot. It helps guarantee stability.

- Document Everything: Keep a log of your readings, including conditions and locations. It’s invaluable for future reference.

- Clean Regularly: Maintain your meter’s pins or sensors. A little cleaning goes a long way!

Importance of Calibration

Calibration is essential for getting accurate moisture meter readings, as it guarantees that your measurements align with established standards. Here’s why it matters:

- Precision: Even a tiny deviation (1-2%) can impact material quality and safety.

- Consistency: Regular calibration minimizes measurement errors, helping you make reliable decisions.

- Longevity: Proper calibration can extend sensor longevity, making your investment worthwhile.

In industries like construction and agriculture, calibration is vital. I recommend calibrating your meter before job sites to keep things smooth. Also, keep records of calibration dates; it’ll help you track performance. Remember, a well-calibrated meter means fewer surprises and better outcomes—nobody wants unexpected moisture levels, right? So, let’s keep those meters in check!

Choosing the Right Meter for Your Needs

How do you choose the right moisture meter for your needs? First, consider the application context. Here are three key factors to guide your choice:

- Meter Features: Pin-type meters are great for precise readings in wood but can damage surfaces. Pinless meters are non-invasive and good for quick scans of larger areas.

- Depth of Measurement: If you need shallow subsurface readings, pinless meters are your friend. For deeper inspections, gravimetric methods are accurate but less practical.

- Material Compatibility: Different materials require different approaches. Wood loves pin-type meters, while drywall and concrete might prefer pinless options.

In short, think about your specific needs, and you’ll find the perfect moisture meter companion!

Frequently Asked Questions

Can Moisture Meters Damage the Surfaces They Measure?

Yes, moisture meters can damage surfaces. I’ve noticed that surface sensitivity matters; pin-type meters can leave marks, while pinless ones maintain measurement accuracy without causing harm. Choosing the right tool is essential for preserving aesthetics.

How Often Should I Calibrate My Moisture Meter?

I’d recommend calibrating my moisture meter based on its usage frequency. For consistent meter accuracy, daily use needs more frequent checks, while intermittent testing often requires calibration before each new sample to guarantee reliable results.

What Are the Signs of a Malfunctioning Moisture Meter?

I’ve noticed that signs of a malfunctioning moisture meter can include inconsistent readings and physical damage. It’s essential to check calibration frequency for different moisture meter types to guarantee accurate performance and reliable results.

Are There Specific Meters for Different Wood Types?

When measuring moisture, I’ve found specific sensors really shine with certain wood types, enhancing meter accuracy. Choosing the right tool boosts readings, ensuring I get precise data without damaging the beautiful finish of my projects.

How Do Environmental Conditions Affect Moisture Readings?

Environmental conditions, like humidity levels and temperature fluctuations, really impact moisture readings. I’ve noticed that higher humidity makes readings spike, while colder temps can keep wood moisture higher than expected. Adjusting for these factors is essential.