When I inspect for electrical hazards, I focus on a few critical areas. First, I check for unsafe equipment conditions—think frayed cords or loose connections. Next, I assess grounding and bonding—make sure everything’s securely grounded to avoid nasty surprises. I also look for GFCI outlets in wet areas, plus check that extension cords are fit for the job. Remember, staying sharp on safety is key. Stick around, and you’ll uncover some expert tips next!

Key Takeaways

- Inspect for frayed insulation and tight connections in branch wiring to prevent electrical shorts and fires.

- Check circuit breakers for appropriate sizing, labeling, and ensure no double-tapped breakers are present.

- Verify the functionality of GFCI outlets, especially in wet areas, to enhance shock protection.

- Assess grounding resistance, aiming for values below 25 ohms, to ensure effective grounding and bonding.

- Examine flexible cords for damage and ensure they are suitable for specific tasks, avoiding hazardous placements.

Electrical Equipment Condition and Installation

When it comes to inspecting electrical equipment, I’ve found that paying attention to the condition and installation can make all the difference—especially if you want to avoid a shocking surprise later on! Here are some key points to take into account:

- Main Panel Check: Confirm it’s securely mounted and accessible, with labels for circuit identification. Look for signs of overheating or damage.

- Circuit Breaker Inspection: Verify breakers are the right size and type for their circuits, and check for double-tapped breakers.

- Branch Wiring: Examine for frayed insulation and tight connections. Don’t forget to check junction boxes!

- Device Condition: Inspect light fixtures and outlets for wear; confirm GFCI outlets are functioning. Additionally, ensure that all testing equipment is regularly calibrated to maintain accuracy in electrical testing for optimal safety.

Grounding and Bonding

While it might not be the most glamorous topic, grounding and bonding are essential for keeping electrical systems safe and reliable. Here’s what you need to know:

- Grounding Techniques: These stabilize equipment enclosures, preventing shocking surprises. They also limit voltage surges from lightning or accidents.

- Bonding Requirements: Bonding guarantees everything is connected, eliminating potential differences that can cause shocks. Proper bonding reduces stray voltage risks, making operations safer.

- Inspection Tips: Check grounding electrode connections and bonding clamps regularly. A good rule? Aim for grounding resistance below 25 ohms—closer to 1 ohm is even better!

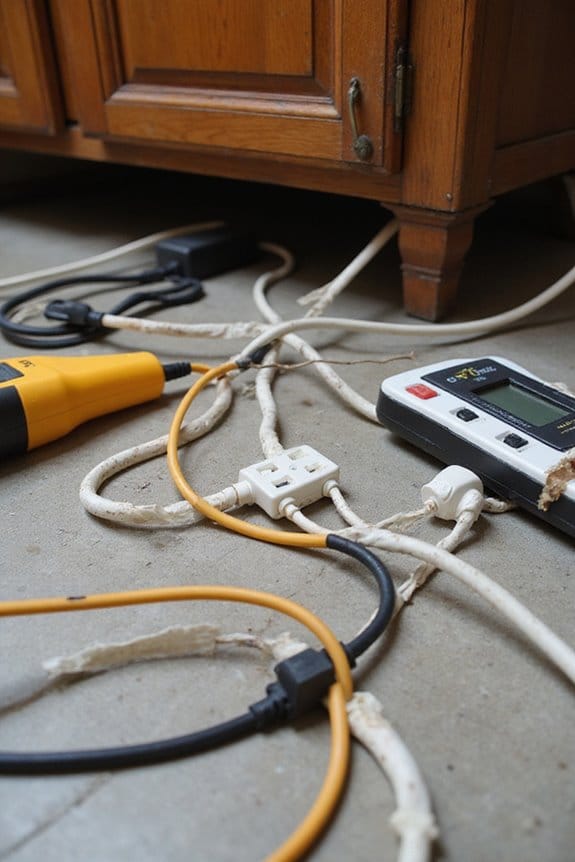

Flexible Cords and Extension Cords

Flexible cords and extension cords are handy tools that make our lives easier, especially when we need power in places where outlets aren’t readily available. However, it’s essential to prioritize cord safety through regular cord inspections. Here’s what I recommend checking:

- Condition: Look for damage, such as cracks or exposed wires. Any visible cuts mean it’s out of service.

- Type: Verify cords match the task. For wet areas, use cords rated for moisture.

- Placement: Don’t run cords through doorways or leave them lying in water.

- Grounding: Use three-prong plugs where grounding is necessary, and GFCIs in wet environments. Additionally, ensure that cords comply with local electrical specifications to prevent safety hazards.

Work Practices and Lockout/Tagout Procedures

Powering down equipment safely isn’t just about unplugging it and calling it a day. It involves thorough hazard identification and following proper lockout procedures. Here’s how to do it right:

- Understand Hazards: Know what types of hazardous energy are present before you start.

- Notify Others: Always inform team members and operators about the shutdown.

- Isolate Energy Sources: Make sure to disconnect all energy sources—electric, hydraulic, and so on.

- Apply Locks and Tags: Use unique locks and clear tags on all energy isolating devices to prevent accidental re-energization.

- Verify Safety: Before any work begins, check for absent voltage.

Training, Compliance, and Safety Awareness

When it comes to keeping our electrical systems safe, training and compliance aren’t just optional—they’re fundamental. Here’s why:

- Training Requirements: Completing accredited electrical courses and apprenticeship programs prepares us to tackle real-world challenges. High school diplomas or GEDs are the starting point.

- Compliance Standards: Knowing the National Electrical Code and local regulations is essential. Regular updates mean we need to stay informed.

- Certification: Achieving Certified Electrical Inspector status shows we comprehend safety protocols and can identify hazards. Plus, re-certification keeps us sharp!

- Safety Awareness: It’s important to recognize risks like overloaded circuits and improper grounding. Remember, a little safety goes a long way—don’t skip that PPE!

Workplace Conditions and Environment

While it might seem like electrical safety is all about the equipment, the workplace environment plays a crucial role too. Here are some essential points to take into account during your environmental assessments:

- Workplace Hazards: Check for wet or damp areas. Equipment needs proper ratings to guarantee safety.

- Access and Lighting: Verify electrical panels are well-lit and easily accessible. You don’t want to fumble around in the dark!

- Housekeeping: Keep floors dry and clear of clutter. Tripping over a cord is embarrassing and dangerous.

- Hazardous Atmospheres: Identify any dust or vapors that could increase ignition risk.

Frequently Asked Questions

What Personal Protective Equipment Is Necessary for Electrical Inspections?

When it comes to electrical inspections, it’s essential to have the right protective gear. Following safety protocols like using arc-rated clothing, insulated gloves, and face shields can keep you safe from potential hazards.

How Often Should Electrical Equipment Be Inspected for Hazards?

When considering inspection frequency, I guarantee electrical equipment undergoes regular maintenance. Depending on condition, I inspect at least annually, but if issues arise, I increase frequency to prevent hazards and maintain safety standards.

What Should Be Done if an Electrical Hazard Is Identified?

What would you do if you spotted an electrical hazard? I’d prioritize hazard mitigation by isolating the area, notifying supervisors, and preparing an emergency response to guarantee safety and compliance before making any repairs.

Are There Specific Regulations for Inspecting Residential Electrical Systems?

Yes, there’re specific regulations for inspecting residential electrical systems. I always follow the residential codes and use a thorough inspection checklist to guarantee every aspect meets safety standards and compliance requirements for homeowners’ peace of mind.

What Are Common Signs of Electrical Failure to Look For?

Last week, I noticed flickering lights in my kitchen and burnt outlets. These signs often indicate overloaded circuits or faulty wiring. It’s essential to address these issues promptly to prevent potential electrical fires or hazards.