To keep your power tools in top shape, I recommend a few key practices. First, clean them regularly; a simple brush or microfiber cloth works wonders. Next, stick to a lubrication schedule with quality greases to avoid wear. Don’t forget cooling; let tools rest after heavy use. Also, store batteries at a 40-60% charge in a cool spot. Finally, inspect your tools often. Curious about more details? There’s plenty more to explore!

Key Takeaways

- Regularly clean tools with a soft brush or compressed air to remove dust and debris for optimal performance.

- Implement a lubrication schedule using high-quality greases to reduce friction and prevent costly repairs.

- Allow tools to cool down after heavy use and maintain proper ventilation to avoid overheating.

- Store batteries at 40-60% charge in a cool, dry place and avoid overcharging to extend battery life.

- Inspect tools before use for defects and ensure a clean, well-lit workspace to enhance safety and efficiency.

Cleaning and Debris Removal

When it comes to keeping your power tools in top shape, cleaning and debris removal are absolutely essential. Trust me, a little effort goes a long way! Here’s how I do it:

- Dust Removal: I always use a soft brush or microfiber cloth after every use. It’s amazing how much dust can accumulate!

- Compressed Air: For vents and internal spaces, a canister of compressed air works wonders.

- Vacuum Cleaners: They’re my best friend for sawdust, especially with woodworking tools.

- Thorough Cleaning: Don’t forget to clean small crevices and vents periodically; it helps with tool sanitization. Additionally, regular calibration of tools not only enhances performance but also ensures accuracy in measurements, which is essential for effective use.

Lubrication Practices

To keep your power tools running smoothly, proper lubrication practices are just as important as regular cleaning. Here are some tips I find helpful:

- Establish a Schedule: Tailor your lubrication frequency to how often you use the tools. Check the manufacturer’s recommendations; they know best!

- Choose the Right Grease: Use high-quality greases suited for your tool’s specific needs. Trust me, avoiding generic greases can save you from costly repairs.

- Apply Correctly: Guarantee even grease application. Too much can actually increase friction—who knew?

- Monitor and Adjust: Keep track of when you lube up. If conditions change, so should your schedule. Additionally, consider the battery life and compatibility of your tools, as proper lubrication can enhance their performance and longevity.

Cooling and Storage

Maintaining ideal cooling and storage conditions for your power tools is essential, especially after a long day of work. Here are my top tips:

- Cool Down: Always let your tools cool down after heavy use to prevent overheating. Trust me, it’ll save you from future headaches.

- Ventilation: Guarantee proper ventilation while using your tools. This helps with heat dissipation, so no sweaty palms!

- Cleaning: Regularly inspect and clean air vents and heat sinks. Dust buildup can be sneaky and harmful.

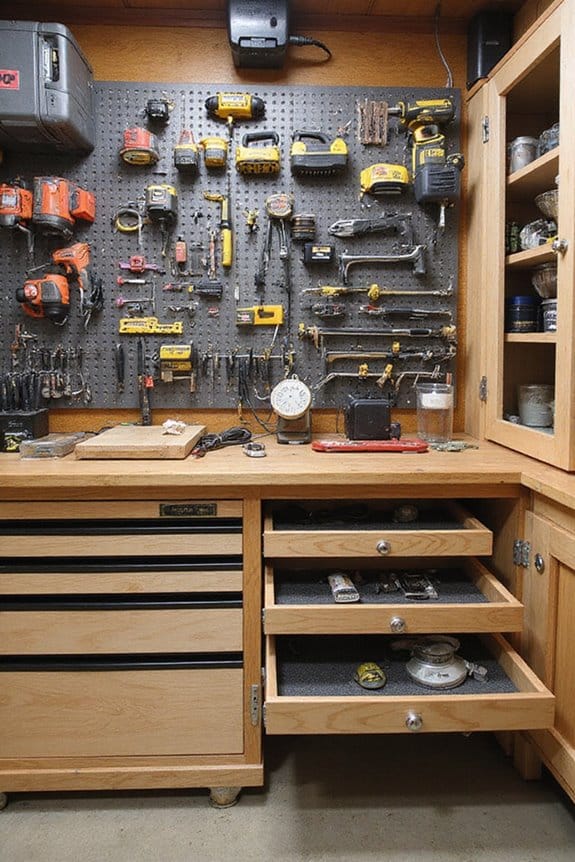

- Storage Solutions: Store your tools in a dry, well-ventilated area. Using protective covers keeps them safe from dust.

Battery Maintenance

Battery maintenance can seem like a challenging task, but I promise it’s simpler than it sounds. Here are some tips to help you keep your batteries in top shape:

- Charge Cycles: Discharge your battery until you notice a significant power drop, then let it rest for two hours before charging. Charge overnight for a full battery lifespan.

- Storage: Keep batteries at 40-60% charge when not in use. Store them in a cool, dry place and check the charge every few months.

- Avoid Overcharging: Use chargers with maintenance modes to prevent unnecessary stress on the battery. Additionally, understanding battery life and capacity can help you choose the right charging practices to maximize performance.

Inspections and Routine Checks

While it might seem like a hassle, regular inspections and routine checks are essential for keeping your power tools running smoothly. Here’s how I handle it:

- Daily Visual Checks: I look for cracks or damage on the casing and inspect cords for fraying.

- Functional Testing: I make sure the tool starts, stops, and operates without strange noises.

- Inspection Frequency: I use a checklist to keep it consistent—every day before use.

- Documentation: I note any issues and tag tools needing repairs, keeping a record of their condition. Additionally, ensuring tools are well-structured toolkits can minimize damage risk during transport and enhance usability.

Sharpening and Component Care

After keeping a close eye on your tools with regular inspections, the next step is sharpening and caring for their components. Here are some key points to remember:

- Sharpening Angles: Each tool has a specific angle that guarantees peak edge performance—get it right!

- Honing Techniques: After sharpening, use honing to remove burrs and refine the edge. Trust me, it makes a difference.

- Slow Speed: When using a grinder, keep it slow (around 1,750 RPM) to prevent overheating.

- Stropping: Finish with a leather strop to align those microscopic edge teeth for a razor-sharp finish.

Cleaning and lubricating components regularly will also extend lifespans and keep your tools in tip-top shape. Don’t overlook these steps—your tools will thank you!

Choosing the Right Tools

Choosing the right tools can feel like a challenging task, especially when you’re faced with so many options out there. I’ve found that following a few simple guidelines makes tool selection a breeze.

- Identify Project Requirements: Know what tasks you’ll tackle, like drilling or cutting, and match tools to the materials involved.

- Consider Frequency of Use: If you’re a weekend warrior, go for cost-effective tools. For pros, invest in durable options.

- Evaluate Ergonomics: Opt for tools with comfortable grips to reduce fatigue.

- Assess Power Source: Decide between corded or cordless based on mobility needs. Additionally, ensure that the tools you choose have adjustable speed and torque settings to handle different materials effectively.

Safe Operating Procedures

When it comes to using power tools, following safe operating procedures isn’t just a good idea—it’s crucial for keeping you and others safe. Here are some key practices to keep in mind:

- PPE: Always wear gloves, safety glasses, and appropriate footwear to protect yourself.

- Tool Inspection: Check your tools before use. Look for defects and verify everything’s functional.

- Operating Environment: Maintain a clean, well-lit workspace and secure your workpiece to prevent slips.

- Tool Handling: Unplug tools when not in use, and never carry them by the cord.

- Emergency Preparedness: Know where emergency equipment is located, like first aid kits.

Staying safe isn’t just smart; it makes your work a lot more enjoyable too!

Understanding Manufacturer Guidelines

Although I know it can be tempting to dive right into using your power tools, understanding manufacturer guidelines is essential for ensuring their longevity and performance. Here’s why sticking to those specifications is key:

- Regular Cleaning: Clean your tools after each use, especially air vents, to prevent overheating.

- Maintenance Schedules: Follow the manufacturer’s recommended frequency for checking parts and lubricating moving components.

- Battery Care: Charge batteries as specified—no one likes a dead battery in the middle of a project!

- Proper Storage: Keep tools in dry, cool places to avoid rust.

Frequently Asked Questions

How Often Should I Replace My Power Tools?

I usually replace my power tools when I notice key replacement indicators, like declining performance or age over five years. Keeping an eye on tool lifespan helps me avoid unnecessary downtime and costly repairs.

What Are Common Signs of a Failing Power Tool?

Ever feel like your tool’s auditioning for a horror movie? If you notice starting troubles, power drops, odd noises, or overheating, it’s time to contemplate tool maintenance. These performance issues can ruin your projects!

Can I Use Household Cleaners on Power Tools?

I wouldn’t recommend using household cleaners on power tools. For tool maintenance, I stick to safer cleaning methods like mild soap and water, which protect the surfaces without risking damage or reducing performance.

How Do I Properly Dispose of Old Power Tools?

When disposing of old power tools, I always check local recycling programs and hazardous waste guidelines. It’s essential to guarantee safe handling and prevent environmental contamination, making a responsible choice for our planet’s future.

Are There Specific Brands Known for Durability?

When it comes to power tools, some brands shine like stars in the night sky. I’ve found that DeWalt, Milwaukee, and Makita consistently deliver durability, backed by solid brand comparisons and glowing durability reviews from users like me.